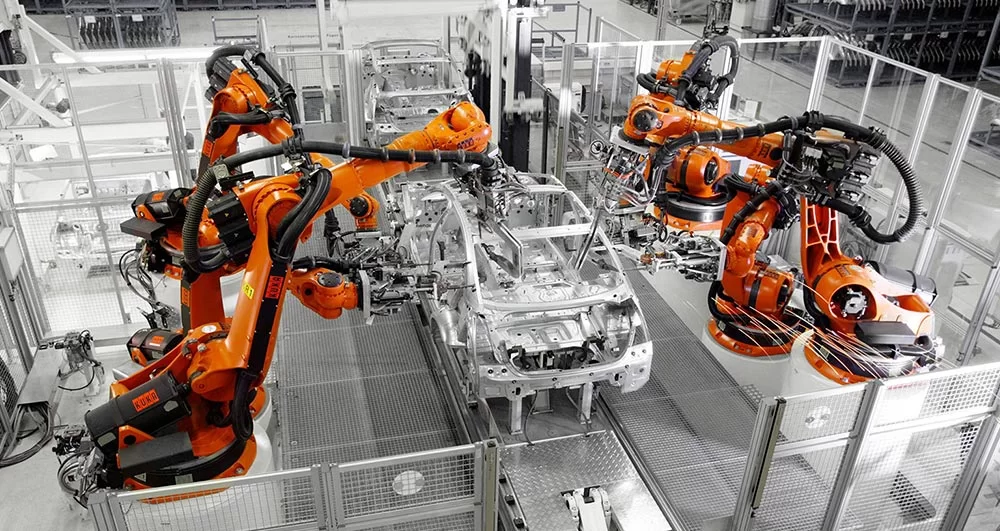

The future of workplace safety is here, and Kuka robots are leading the way. As technology continues to rapidly evolve, so too does the way we prioritize safety in the workplace. Robotics have become an essential part of almost every industry and have revolutionized the way businesses produce their goods and services. This is especially true for Kuka robots, which are being used across the world to reduce the risk of workplace injuries and increase productivity.

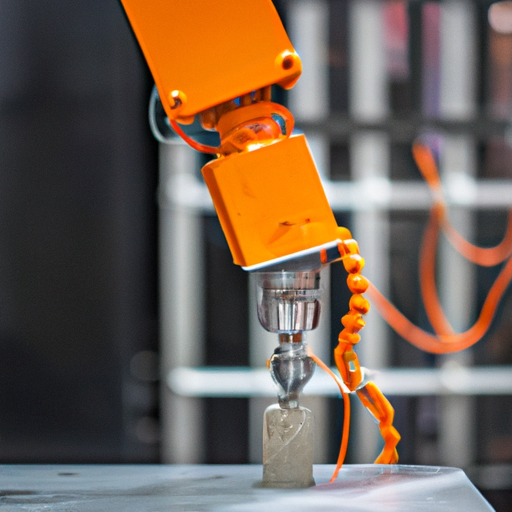

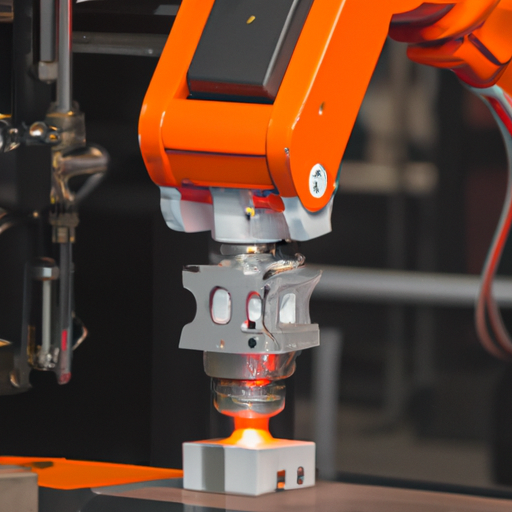

At Kuka robots, safety is at the core of their mission. They are leveraging advanced sensors, 3D vision systems, and artificial intelligence software to create robots that can detect potential hazards and react quickly and reliably. Their robots have a variety of capabilities, such as precise handling of hazardous materials, precise control over large machinery, and monitoring of safety protocols. The end result is an unprecedented level of safety in the workplace.

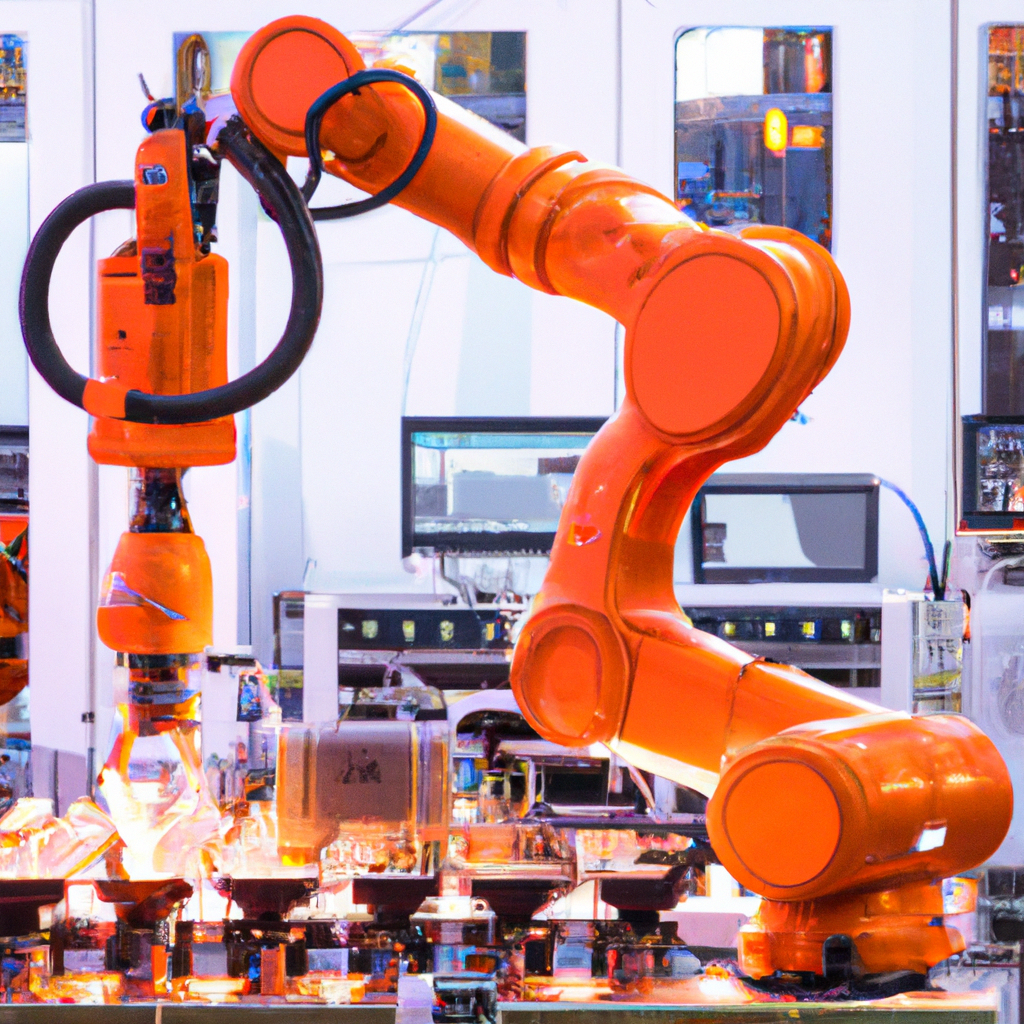

Kuka robots are also helping companies reduce their costs and improve their processes. By using robots to automate tasks and operations, companies can reduce the need for manual labor and potentially dangerous situations. At the same time, they can increase productivity and improve their overall efficiency. With the help of Kuka robots, businesses can gain a competitive edge in their respective industries.

In this blog post, we will explore the ways in which Kuka robots are revolutionizing workplace safety and how they are making a difference in the lives of workers. We will discuss the various ways in which Kuka robots are helping businesses reduce their costs and increase their efficiency and why they are a crucial part of the future of work. Finally, we will explore the potential for Kuka robots to help improve safety management across multiple industries. Join us as we take an in-depth look at Kuka robots and how they are revolutionizing workplace safety.